In business, there is a distinct difference between motion and progress.

Many organizations confuse the two. They are constantly “putting out fires,” launching reactionary initiatives, and throwing budget at problems in the hopes that something sticks. This is motion. It feels like work, but it rarely leads to sustainable growth. It usually leads to burnout and budget depletion.

Progress, on the other hand, is calculated. It is the result of a systematic approach to problem-solving where every failure is a data point and every success is standardized.

Enter the PDCA Cycle.

Whether you are a startup founder looking to find product-market fit, a marketing director trying to optimize ad spend, or an operations lead streamlining a supply chain, the PDCA Cycle is the scientific method applied to your business strategy. It is the framework that turns chaos into clarity.

In this comprehensive guide, we will break down exactly what the PDCA Cycle is, how to implement it step-by-step, and why it is the secret weapon of the world’s most efficient c.ompanies.

What is the PDCA Cycle?

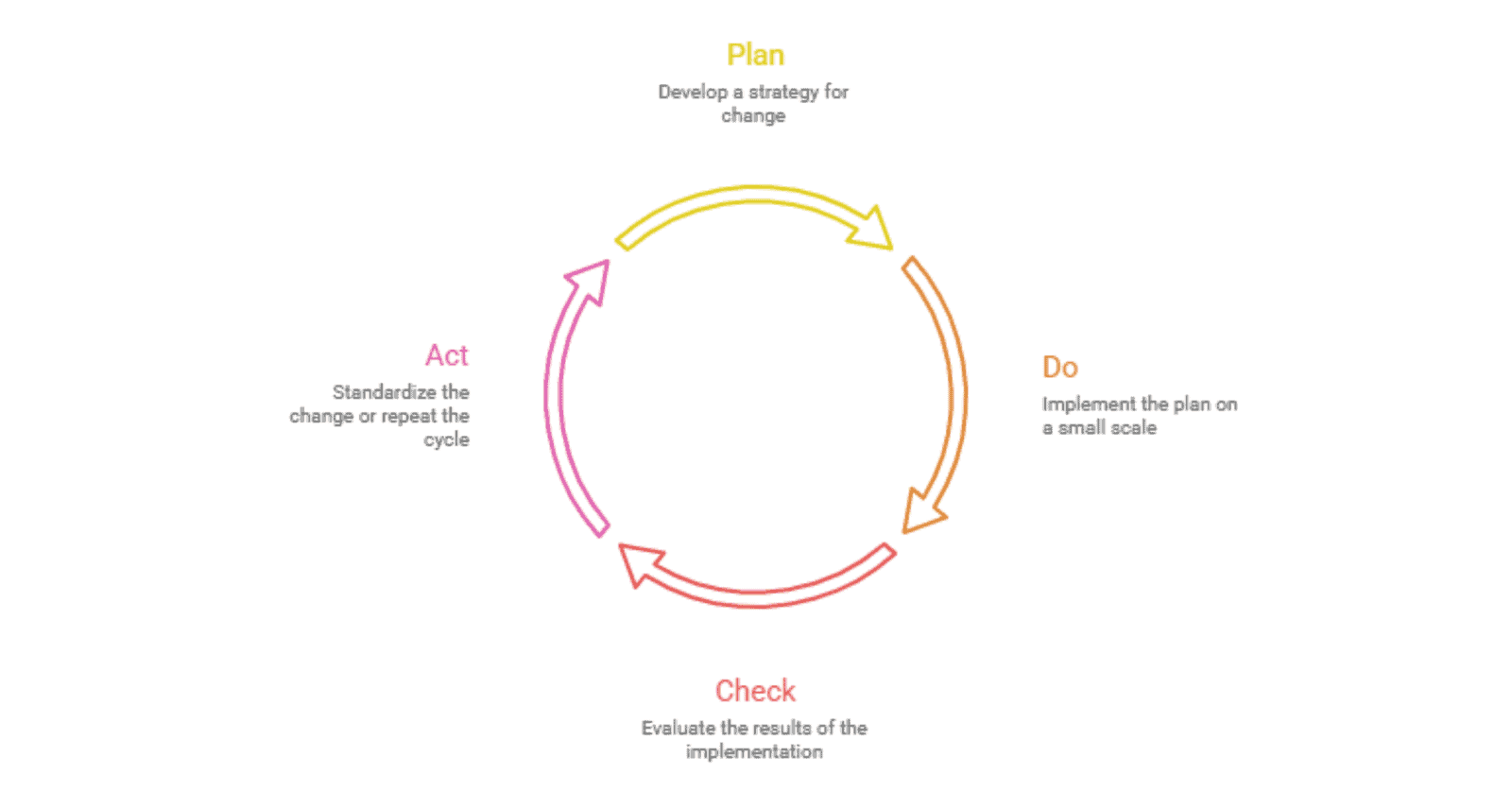

The PDCA Cycle, standing for Plan-Do-Check-Act, is an iterative management method used for the control and continuous improvement of processes and products.

While it is often referred to as the Deming Cycle (named after W. Edwards Deming, the father of modern quality control), its roots actually trace back to Walter Shewhart in the 1920s. Deming later popularized the concept in Japan post-WWII, helping to spark the Japanese economic miracle and the rise of methodologies like Kaizen (continuous improvement).

The Power of the Loop

The most critical aspect of PDCA is that it is a cycle, not a straight line. In traditional project management, you might reach a “finish line” and move on. In the PDCA framework, the “finish line” of one cycle is merely the starting line for the next.

It rejects the idea that a process is ever “perfect.” Instead, it operates on the assumption that everything, from your sales script to your warehouse logistics, can always be 1% better.

The 4 Stages of PDCA Explained

To truly master this framework, you need to move beyond the acronym and understand the strategic intent behind each phase.

1. PLAN: Identify, Analyze, and Hypothesize

The “Plan” phase is often where businesses fail before they even begin. It is tempting to identify a surface-level symptom and immediately jump to a solution. However, PDCA requires you to dig deeper.

Step A: Root Cause Analysis Don’t just look at the problem, e.g., “Sales are down”. Look for the root cause. Use tools like the 5 Whys or a Fishbone Diagram to peel back the layers.

- Symptom: Sales are down.

- Why? Leads have decreased.

- Why? Website traffic has dropped.

- Why? Our organic search rankings fell.

- Why? Our site speed dramatically decreased after the last update.

- Root Cause: Poor technical SEO implementation during the last update.

Step B: Establish Goals Once you know the root cause, you need a baseline and a target. “Improve site speed” is not a plan. “Reduce page load time from 4.5s to 2.0s by the end of Q3” is a plan.

Step C: Formulate a Hypothesis. What do you think will solve this? This isn’t a guess; it’s a calculated prediction based on data.

2. DO: Test on a Small Scale

The “Do” phase is widely misunderstood. Many leaders interpret “Do” as “Roll it out to everyone.”

In the PDCA context, “Do” means “Test.”

This is the experimentation phase. You implement your solution in a controlled environment to minimize risk. If you are changing a sales script, have only your top three performers use it for a week. If you are changing a manufacturing material, produce a single small batch.

Key Activities in the ‘Do’ Phase:

- Execute the plan on a micro-scale.

- Gather real-time data.

- Document unexpected side effects.

- Do not disturb the core operations of the business yet.

Treat this phase like a laboratory experiment. You aren’t trying to change the world yet; you are trying to prove your hypothesis.

3. CHECK: Review the Results

This is the moment of truth. In the “Check” phase, sometimes called “Study”, you compare your actual results from the “Do” phase against the objectives you set in the “Plan” phase.

You must strip away ego and emotion here. The data does not care about your gut feeling.

Ask the hard questions:

- Did we achieve the goal?

- If yes, was it by the margin we expected?

- If no, what variables did we fail to account for?

- Did the solution create new, unforeseen problems? (e.g., We increased site speed, but the new design lowered conversion rates).

If the results don’t match your hypothesis, that is not a failure, it is valuable data. It means you saved the company the cost of a full-scale rollout of a flawed idea.

4. ACT: Standardize or Adjust

The final phase is the decision point. Based on your analysis in the “Check” phase, you have two paths:

Path A: Standardize (Adopt). If the test was a success, you “Act” by implementing the solution across the entire organization. You update your Standard Operating Procedures (SOPs), train the rest of the team, and make this the new “normal.”

- Crucial: Once standardized, this becomes the new baseline for the next planning phase.

Path B: Adjust (Abandon or Iterate). If the test failed or yielded lackluster results, you adjust. You return to the “Plan” phase with new knowledge. You refine your hypothesis and prepare for a new cycle.

Real-World Examples: PDCA in Action

To see how versatile this cycle is, let’s look at two distinct business scenarios.

Scenario 1: Marketing Optimization (The Email Dilemma)

Context: A SaaS company notices their newsletter open rates have dropped to 12%.

- Plan: They analyze the data and hypothesize that the subject lines are too generic. They set a goal to reach a 20% open rate. They create three “curiosity-gap” subject line variations.

- Do: They do not send this to their entire list of 50,000 people. They send an A/B test to a random sample of 2,000 subscribers (1,000 get the old style, 1,000 get the new style).

- Check: The data comes back. The old style had a 12% open rate. The new style had an 18% open rate. It didn’t hit the 20% goal, but it is a significant improvement.

- Act: They determine the improvement is statistically significant. They roll out the new subject line style to the remaining 48,000 subscribers and update their copywriting guidelines to favor curiosity gaps.

Scenario 2: Operations (The Warehouse Bottleneck)

Context: An e-commerce fulfillment center is missing shipping deadlines on Mondays.

- Plan: The floor manager observes that Monday mornings are chaotic because weekend orders pile up, and printers jam due to volume. Hypothesis: Staggering shift start times and upgrading one printer will alleviate the bottleneck.

- Do: For two weeks, they bring in 3 packers one hour early on Mondays and rent a high-speed industrial printer.

- Check: They review the “Time to Ship” metrics. Monday delays dropped by 85%. However, labor costs rose slightly due to the early shift differential.

- Act: The cost of the labor is far lower than the cost of refunded shipping fees and lost customers. The manager permanently changes the Monday roster and submits a capital request to purchase the printer.

Why Most Businesses Fail at PDCA

If PDCA is so effective, why isn’t every company efficient? The failure usually lies in human psychology, not the framework itself.

1. The “Check” Phase is Ignored This is the most common pitfall. Companies Plan and Do, and then… they just keep Doing. They assume the solution worked without verifying the data. Without the “Check,” you are flying blind.

2. Analysis Paralysis in the “Plan” Phase Some teams are so afraid of making a mistake that they spend months planning. PDCA favors action. A “good enough” plan tested today is better than a “perfect” plan tested next year.

3. Fear of Failure in the “Do” Phase In a healthy PDCA culture, a failed test is celebrated because it provided knowledge. in a toxic culture, employees fudge the numbers in the “Check” phase to hide the failure of the “Do” phase. This breaks the cycle and institutionalizes mediocrity.

The Benefits of Adopting the PDCA Mindset

When you successfully embed PDCA into your company DNA, the benefits compound over time:

- Risk Mitigation: By testing small (Do) before scaling (Act), you avoid catastrophic failures. You never bet the whole farm on a hunch.

- Scalability: Growth breaks processes. PDCA ensures that your processes evolve alongside your revenue.

- Empowerment: It gives employees a framework to solve their own problems. Instead of complaining about a broken process, they can propose a PDCA cycle to fix it.

- Competitive Advantage: While your competitors are guessing, you are iterating. Over the course of a year, those small 1% improvements add up to a dominant market position.

Conclusion: Stop Guessing, Start Cycling

Perfection is a myth. There is no such thing as a perfect marketing campaign, a perfect product launch, or a perfect supply chain. There is only the process of getting better.

The PDCA cycle gives you the permission to be imperfect, provided you are disciplined enough to learn from it. It shifts your focus from “being right” to “finding out what works.”

If you feel like your business is stagnant, or if you are overwhelmed by operational chaos, pick one small problem today. Plan a fix. Do a test. Check the results. Act on the data.

Then, do it again.